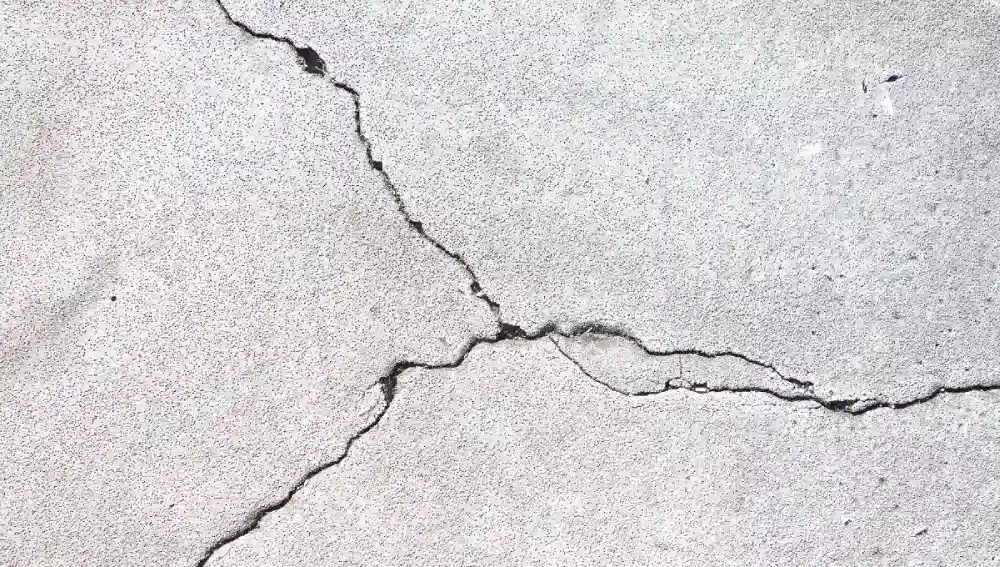

As a homeowner, you might encounter various cracks in different buildings. Understanding the different types of cracks and their underlying causes is crucial for properly diagnosing and addressing them. In this blog, I’ll walk you through 20 common types of cracks, their causes, and the best methods for fixing them.

19 Types of Cracks in Building

Structural Cracks

Structural cracks can compromise the integrity of the building’s structure. Typically caused by overloading, poor design, or foundation issues.

How to Fix It

- Epoxy injection seals cracks. It restores concrete’s strength by injecting thin epoxy under pressure.

- Stitching involves drilling holes on either side of the crack. Then, you insert steel pins or staples to hold the crack together. This method is effective for masonry walls.

Flexural Cracking

Caused by bending stresses in beams and slabs. Appear as vertical cracks on the tension side of the member.

How to Fix It

- Flexural cracks may require epoxy injection to seal the crack and restore structural integrity.

- Adding more reinforcement helps. It can strengthen the affected area.

Settling Cracks

Caused by uneven settling of the foundation. Often due to poor soil conditions or inadequate foundation design.

How to Fix It

- Addressing settling cracks may require underpinning, which involves strengthening or replacing the foundation.

- Other methods can also repair foundations. They include piering or helical anchors. They can stabilize and prevent further movement.

Diagonal Cracks

Indicate shear stresses in the structure. Often caused by differential settling or overloading.

How to Fix It

- Adding steel plates or fiber-reinforced polymer (FRP) wraps can distribute the loads. They also prevent more cracking.

- These materials are bonded to the concrete or embedded inside it.

Crazing

A network of fine, interconnected cracks on the concrete surface. Typically caused by rapid drying or improper curing.

How to Fix It

- Crazing is a cosmetic problem and does not typically affect the concrete’s structural integrity.

- Sealants create a barrier on the concrete. They stop moisture and other factors from getting in.

Thermal Movement Cracks

Caused by the expansion and contraction of building materials due to temperature changes.

How to Fix It

- Thermal movement cracks can be fixed. You fix them by adding expansion joints to the building’s structure.

- Expansion joints allow materials to expand and contract. This prevents stresses that cause cracking.

Horizontal Cracks

Often caused by lateral soil pressure or hydrostatic pressure from groundwater.

How to Fix It

- Horizontal cracks may need anchors or tiebacks. These will stabilize the wall and stop more cracking.

- Anchors are driven into the soil behind the wall, providing a secure connection to counteract the lateral forces.

Initial Shrinkage

Occur in concrete and masonry due to the loss of moisture during the curing process.

How to Fix It

- You can minimize initial shrinkage cracks by proper curing during construction.

- Using curing compounds or wet burlap retains moisture in the concrete. This reduces the risk of shrinkage cracks.

Overloading Cracks

Caused by excessive loads being applied to the structure, beyond its design capacity.

How to Fix It

- Overloading cracks may require structural reinforcement to address the root cause of the issue.

- More steel can be added. It can be in the form of beams or columns. This will spread the loads and stop more cracking.

Settlement

Similar to settling cracks, but caused by the gradual sinking of the entire foundation.

How to Fix It

- Settlement cracks may need underpinning. Or, they may need other foundation repair techniques to stabilize the structure.

- Underpinning involves strengthening or replacing the foundation to prevent further movement and cracking.

Corrosion Cracks

Caused by the expansion of corroded reinforcing steel within concrete. Leading to the cracking of the concrete cover.

How to Fix It

- The corroded steel must be treated by cleaning or replacing the affected sections.

- A repair mortar or coating is then applied to the affected area to restore the concrete’s structural integrity.

Expansion Concrete Cracks

Caused by the swelling of concrete due to chemical reactions, such as alkali-silica reaction (ASR) or sulfate attack.

How to Fix It

- Expansion concrete cracks may require the removal and replacement of the affected concrete.

- Using low-alkali cement or other preventions can help reduce the risk of future cracking from expansion.

Hairline Cracks

Extremely fine cracks that are barely visible to the naked eye. While they may not be a structural concern, they can indicate the presence of more serious issues.

How to Fix It

- The sealant helps protect the concrete from weathering. It also stops the hairline cracks from getting worse.

- Monitoring the hairline cracks over time is key. They may indicate bigger problems early.

Plastic Settlement

Occur in fresh concrete due to the settlement of aggregates and the formation of bleed water at the surface.

How to Fix It

- Proper concrete placement techniques, such as vibration, can minimize plastic settlement cracks.

- Proper consolidation of the concrete helps. This can be done through vibration or other methods. It eliminates voids and reduces aggregate settlement.

Premature Drying

Caused by rapid moisture loss from the surface of fresh concrete, leading to the formation of cracks

How to Fix It

- Premature drying cracks can be prevented by proper curing techniques during the construction phase.

- The application of curing compounds helps retain moisture in the concrete, reducing the risk of rapid drying and cracking.

Plastic Shrinkage

Similar to premature drying cracks, but caused by the evaporation of moisture from the surface of fresh concrete.

How to Fix It

- Plastic shrinkage cracks can be minimized by protecting the concrete surface from wind and direct sunlight.

- Proper concrete mix design is key. It needs an appropriate water-cement ratio. This can also reduce the risk of plastic shrinkage cracks.

Cracks in Roof Slab

This can be caused by a variety of factors, including thermal movement, overloading, or inadequate reinforcement.

How to Fix It

- Cracks in roof slabs may need more reinforcement. This is to fix the underlying structural issues.

- Fixing the root cause of the cracking is key. This cause may be thermal movement or overloading. It stops the problem from happening again.

Cracks in RCC Members

This can be caused by a variety of factors, including flexural stresses, shear stresses, or corrosion of reinforcing steel.

How to Fix It

- Cracks in reinforced cement concrete (RCC) members may need epoxy injection. It seals the crack and restores strength.

- Adding more reinforcement helps. They can strengthen the affected area.

Heaving Crack

Caused by the swelling of soil or expansive clays beneath the foundation, leading to the uplift of the structure.

How to Fix It

- These techniques help counter the upward forces from swelling soil or clays.

- Moisture barriers and soil stabilization techniques can help. They stop soil from expanding. Techniques include chemical treatment and compaction.

Conclusion:

By properly identifying the type of crack and its severity, you can implement the appropriate repair methods to restore structural integrity and prevent further damage. Remember, early intervention is key to maintaining the safety and longevity of your building.