Across the world, governments, businesses, and homeowners are prioritising energy efficiency to reduce carbon emissions, mitigate climate change, and lower energy costs. This trend is increasing the demand for building materials and methods that enhance energy efficiency, such as Insulated Concrete Forms (ICFs).

In today’s Brick & Bolt blog, you will learn more about Insulated Concrete Forms, benefits, and applications.

What are ICF Forms?

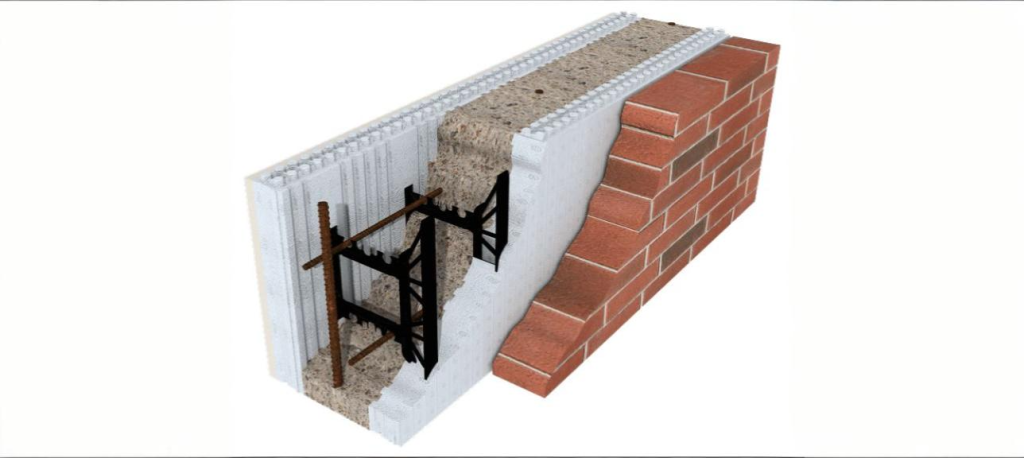

ICF stands for Insulated Concrete Forms, which are used in modern construction methods. It consists of blocks made from an insulating material such as expanded polystyrene (EPS). EPS combines with concrete to deliver superior levels of performance over alternative construction techniques.

Insulated Concrete Forms (ICF) are hollow foam blocks that are stacked into the shape of the exterior walls of a building, reinforced with steel rebar, and then filled with concrete. You can achieve unmatched comfort, energy efficiency, strength, and noise reduction with the aid of insulated concrete formwork.

Types of Insulated Concrete Form Systems

There are three ICF system designs:

- Flat systems: This system is similar to conventional poured walls, with a continuous thickness of concrete through the entire wall.

- Grid systems: This system involves a waffle pattern where the concrete is thicker at some points.

- Post and beam system: This system has horizontal and vertical elements of concrete that are completely encapsulated in foam insulation.

These systems are accepted by codes and have been successfully deployed in many projects.

ICF Wall System Components

You need to understand the ICF wall system’s different components before using it for residential or commercial purposes. They are as follows:

Forms

The foam concrete forms involve expanded polystyrene (EPS) or other types of insulating materials. ICF blocks are specially designed to interlock, forming continuous, strong formworks. These forms are filled with concrete to withstand considerable loads.

Concrete Core

Concrete is the major element of ICF concrete forms. The concrete mix makes the difference between traditional forms and ICFs. Concrete should have a compressive strength of at least 20.67 MPa to support a building’s weight. The building’s load-bearing capacity depends on concrete strength. By using reinforced concrete, you will be able to ensure safety against considerable lateral forces such as winds and seismic activities.

Steel Reinforcement

In ICF walls, steel reinforcement is done in the form of rebars. Concrete has low tensile strength; hence, it is necessary to place rebar inside the concrete core to improve its tensile strength. The rebars are generally placed in horizontal and vertical grids according to the structural requirements and local building regulations.

Insulation

Insulation in ICF forms is created using expanded polystyrene (EPS) foam. This can serve different purposes as it has a high R-value (R-22 to R-30). The R-value measures how well a two-dimensional barrier, such as a layer of insulation, resists the conductive flow of heat in the construction context. This insulation also acts as a moisture retarder, stopping mould growth and maintaining the wall assembly’s durability over time.

Air and Vapour Barrier

Due to the concrete core and tightly sealed insulation, ICF walls serve as an air and vapour barrier, constraining the outside air and moisture. The air barrier helps control air leakage within ICF wall systems. ICF wall systems are designed with minimum joints to maintain air tightness. This improves energy efficiency and makes your home more comfortable to live in.

Furring Stirrups

Furring stirrups are used to create a framework for attaching drywall or exterior cladding to the walls. They help to keep the ICF wall strong and prevent it from sagging over time. You need to install furring stirrups carefully and in an appropriate position to support the loads from the wall finishes. They can also create space for insulation and allow proper drainage around certain parts of the wall, improving the performance of the ICF wall system.

Benefits of Building with ICFs

If you include Insulated Concrete Forms (ICFs) in your house construction, you can expect the following advantages:

Energy Efficiency

The concrete core in ICF walls acts as an air and vapour barrier, stabilising the structure’s internal temperature. ICF R-value ratings often exceed R-22, helping reduce the energy consumption for heating and cooling and lowering utility costs by up to 44% for heating and 32% for cooling.

Structural Benefits

ICF walls provide excellent wind resistance and can withstand winds over 200 mph, making them suitable for hurricane-prone regions. They can also endure well during extreme weather events such as high winds and flying debris. ICF buildings offer excellent sound insulation with sound transmission class (STC) ratings of 50 or higher. ICFs possess an amazing fire rating, typically lasting up to four hours under fire conditions, providing crucial time for evacuations and emergency responses.

Construction Advantages

The construction time of ICF walls is considerably lower than conventional systems and requires a lower number of skilled workers on-site. This process also results in minimal waste. By careful planning, you can reduce the materials required, which also enables recycling.

Cost Considerations for Insulated Concrete Forms

Initially, constructing an ICF building may require a financial investment of approximately 3-5% higher than traditional wood-frame methods. Premium-grade insulated concrete forms are typically pricey, but ICF construction becomes very cost-effective when adding large openings. For instance, the price of ICFs in Uttar Pradesh is approximately ₹1,200 per square foot, while standard wood framing usually costs around ₹1,500 to ₹2,000 per square foot, including both materials and labour.

This construction with ICFs requires a minimal number of labourers. ICF structures will become less expensive over time as they require less energy to heat and cool.

Insurance costs will be minimal as insurance companies identify that ICF homes and buildings are less susceptible to damage from earthquakes, floods, hurricanes, fires, and other natural disasters.

Common Applications of Insulated Concrete Forms (ICFs)

ICFs are used in various applications across the construction industry. Some of the major applications are:

Residential Construction

Since it offers numerous benefits, it’s widely used in residential house construction. You can use this in the construction of small houses for single families as well as housing complexes for multi-family structures.

Underground Applications

ICF blocks are largely used in basements and foundations. In Indian climates, monsoon rains and groundwater concerns are predominant. It is essential to achieve moisture resistance and insulating properties for basements, and ICFs are well suited for that aspect.

Commercial Buildings

Commercial buildings such as office buildings, retail stores, and hospitals require efficient thermal insulation and soundproofing. For better operational efficiency inside the structure, you can choose ICFs for the construction of commercial buildings. Also, structures constructed with ICFs strongly follow commercial energy codes and zoning requirements. This will reduce the difficulty of additional tasks like getting construction approvals, and making them smart choices.

Special Applications

Nowadays, resilient buildings are gaining popularity. Resilient structures are those designed to withstand high winds, seismic activities, and severe weather conditions and include fire and water resistance. ICFs fulfill all these requirements in a budget-friendly way. If you are constructing a house in a disaster-prone area, you can consider ICF concrete forms as a reliable building material.

Conclusion

With cost considerations and practical applications of ICFs, their use is growing rapidly in the Indian construction field. With environmental consciousness, structural safety and comfort taken into consideration, you can choose ICFs for your house’s construction.