Portland cement is a key material used in construction because it’s strong and long-lasting. Surprisingly, the cement we use today started in a kitchen! Joseph Aspdin, a British stone mason, made cement by heating raw ingredients like clay powder and limestone. But now, it is an essential part of building concrete structures. Let us delve deeper into the manufacturing process and applications of Portland cement in various construction projects.

Overview of Portland Cement

Portland cement is a fine powder used as a key binding material in concrete and mortar, providing strength and durability to structures. When mixed with water, sand, and gravel, it forms a strong, durable composite essential for construction. The cement undergoes a chemical process called hydration, binding the materials together and providing the strength necessary for structures to endure heavy loads and harsh conditions.

While indispensable in construction, the production of Portland cement poses environmental challenges, including high energy consumption and CO2 emissions. However, advancements in technology continue to improve its efficiency and reduce its environmental impact.

Composition of Portland Cement

Cement factories are usually found in regions that are rich in raw materials and have easy access to long-distance, effective transportation for both raw materials and completed goods. The principal composition of raw materials used to prepare ordinary Portland cement are as follows:

| S.No | Constituent | Composition (%) | Description |

| 1 | Lime (CaO) | 60-67 | It is Portland cement’s most common ingredient. |

| 2 | Silica (SiO_2) | 17-25 | It makes cement stronger. |

| 3 | Alumina (Al_2O_3) | 3-8 | It helps the cement set more quickly. |

| 4 | Calcium Sulphate (CaSO_4) | 3-4 | It delays the setting time by acting as a retardant. |

| 5 | Iron Oxide (Fe_2O_3) | 3-4 | It gives cement colour and toughness. |

| 6 | Magnesia(MgO) | 0.1-3 | It adds toughness to the cement. |

| 7 | Sulphur | 1-3 | An excessive amount of sulphur can cause instability. |

| 8 | Alkalies (Soda and Potash; (Na_2O and K_2O)) | 0.5-1.3 | In the alkali-aggregate reaction, it is crucial. |

Manufacturing Process of Portland Cement

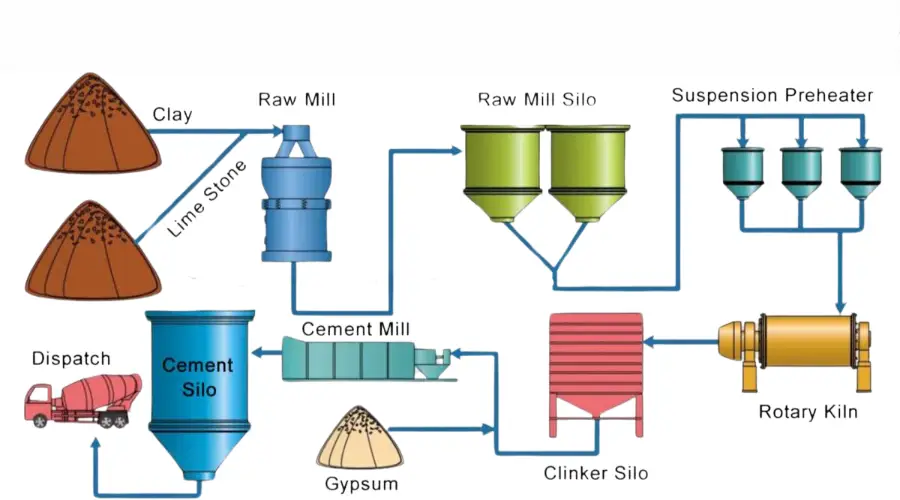

The manufacturing process of Portland cement starts with grinding and mixing the raw materials at specific proportions. Then the mixture in a kiln is heated at 1350–1500°C to form a sintered product. The steps to be followed for manufacturing Portland cement are as follows:

Step 1: Mixing of Raw Materials:

The production of Portland cement begins with the selection and preparation of key raw materials, including calcium, silicon, iron, and aluminum. These materials are combined in specific proportions to ensure the desired chemical composition and properties of the cement. The table is a list of the ingredients used to create Portland cement.

| S.No | Calcareous Materials | Silicon | Aluminium | Iron |

| 1 | Limestone | Clay | Clay | Clay |

| 2 | Marl | Marl | Shale | Iron ore |

| 3 | Calcite | Sand | Fly ash | Mill scale |

| 4 | Aragonite | Shale | Aluminium ore refuse | Shale |

| 5 | Shale | Fly ash | Blast furnace dust | |

| 6 | Sea Shells | Rice hull ash | ||

| 7 | Cement kiln dust | Slag |

The mixing procedure of cement involves two methods:

- Dry process

In the dry process, the calcareous and argillaceous raw materials are crushed into 2–5 cm pieces in gyratory crushers, followed by grinding into fine particles in ball or tube mills. To guarantee a consistent composition of the finished product, the ingredients are stored in hoppers and stored in silos before being fed into the rotary kiln.

- Wet process

In the wet process, the raw ingredients are processed into powder and kept in silos. The clay is cleaned in mills to remove organic contaminants and then combined with the powdered limestone in grinding mills to form a slurry. The slurry ratio is carefully adjusted as the mixture is transferred into a basin for further composition adjustments before being fed into the rotary kiln

Step 2: Burning of Raw Materials:

During the burning process, the raw materials rotate at 1-2 rpm in a rotary kiln. The kiln is made of steel tube that is 90–120 meters long, 2.5–3 meters in diameter, and slightly angled. It is lined with refractory bricks. Flames are produced when raw materials are fired in the kiln by hot gases, oil, or powdered coal.

The raw material passes through three zones:

- The calcination zone (1000°C), (where limestone breaks down into lime)

- The drying zone (400°C), (where moisture evaporates)

- Clinkering zone (between 1500 and 1700°C),(where Clay and lime interact to form clinkers).

These clinkers, which are tiny, hard stones that measure 5 to 10 mm, are gathered in trolleys after being cooled by air.

Step 3: Grinding of Clinkers

The cooled clinkers are ground into a fine powder in ball or tube mills, and 2-3% gypsum is added as a retardant. By doing this, the cement won’t set too soon after being combined with water. Proper curing is made possible by the insoluble compound gypsum, which slows down the setting and hardening process. The reaction is:

3CaO.Al₂O₃ + xCaSO₄·7H₂O → 3CaO.Al₂O₃·xCaSO₄·7H₂O

Step 4: Storage and Packaging

Finally, the cement is packaged for sale in 50-kilogram bags or containers and kept in silos.

Application of Portland Cement

Portland cement is a versatile building material that can be used in various construction projects and is known for its stability and longevity in supporting structures. However, its applications range from small-scale structures to large civil engineering projects:

Urban Infrastructure: It supports the functioning and development of a city by creating public steps, seats, planters, trash cans, stairs, and ornamental fountains.

Utility structures: Any above- or below-ground utilities that provide service to customers are utility structures. These include telephone poles, columns, and streetlights which can be regularly used.

Transportation: Structures that help to enable the movement of goods or people from one to another come in this category. Eg: roads, canals, railroads, etc.

Large-Scale Civil Projects: Bridges, tunnels, dams, piers, buildings, and other large-scale civil projects can be built using Portland cement.

Flooring and Repairs: In this phase, the cement grout is used to patch concrete cracks and assist in creating stable floors.

Masonry Work: While building a structure, bricks and stones are bound together with cement mortar.

Conclusion

Portland cement is frequently employed in a variety of construction projects to achieve strength and longevity when bearing massive structures. Since the construction industry invented Portland cement, people have decided to use this cement in their projects as technology has advanced.