The roof slab is an important component of the building. It provides the necessary support and separates the different levels. It plays a major role in withstanding load and ensuring the building’s safety, security, and durability. As load-bearing is the roof slab’s primary purpose, necessary reinforcement must be placed within the structure. So, here we look at roof slab reinforcement, its purpose, reinforcement materials, and the design and construction process.

What is Roof Slab Reinforcement?

The Roof Slab is a flat load-bearing section of the building supported by beams, columns, and a structural framework. Roof Slab Reinforcement incorporates reinforced steel bars or mesh into the concrete slab to enhance structural strength and durability. It helps the slab withstand tensile stresses acting on the structure and protects it from cracking.

Primary Purposes of Reinforcement in Roof Slab

- Reinforcement in roof slabs plays a major role in enhancing overall structural integrity and durability.

- It provides the necessary tensile strength and improves the resistance against tensile forces.

- It helps control the cracks caused by the slab pulling apart and enhances durability.

- Improves the load-bearing capacity of the slab.

- It boosts the ductility of the concrete by allowing it to deform under stress without causing a sudden failure.

- It helps the slab withstand thermal expansion and contraction.

Reinforcement Materials Used for Roof Slab

Steel Bars (Rebars)

Steel bars or rebars are the most commonly used reinforcement in the construction of roof slabs. The steel bars vary based on the diameters and grades. The most widely used steel bars are:

- Mild Steel (MS) Bars: They provide good strength and are easily bendable.

- Thermo-Mechanically Treated (TMT) Bars: They provide high strength, durability, and corrosion resistance and give flexibility and strength.

- High Yield Deformed (HYSD) Bars: They are designed with a deformed surface suitable for bonding with concrete and providing tension and shear resistance.

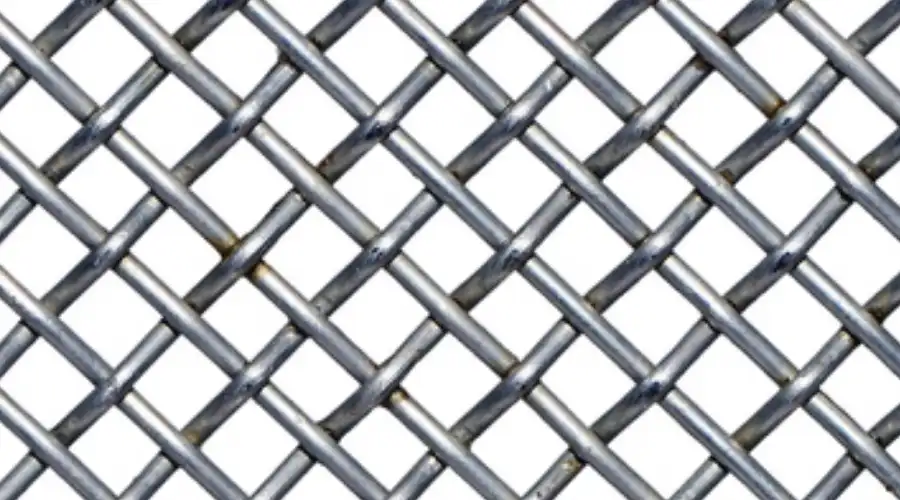

Steel Mesh

Steel mesh is a grid or network structure of steel wire that is welded together to provide the necessary reinforcement for smaller slabs and distribute reinforcement uniformly.

Steel Plates and Strips

Steel plates and strips can be used as reinforcement within the slab to provide additional strength. These plates and strips are used for higher load-bearing slabs and structures designed for specialised applications.

Fiber Reinforced Polymer (FRP) Rebar

This reinforcement offers high strength and good resistance to corrosion. This composite rebar is used in extreme climatic and harsh environments.

Pre-stressed and Post-tensioned Tendons

The tendons are made from high-strength steel and are widely used in pre-stressed concrete slabs. They are directly installed, and concrete is poured over them to create the necessary compression to withstand bending.

Design Considerations for Roof Slab Reinforcement

Load Calculations

The loads acting on the slab must be considered while designing the roof slab. The loads that need to be considered include:

- Dead Load: It measures the self-weight of the reinforcement and concrete used in the slab.

- Live Load: It measures variable loads on the roof slab, such as traffic, furniture, equipment, and other loads.

- Other Loads: It also includes the wind, seismic, imposed, and other concentrated loads acting on the structure.

Span and Supports

The length of the span plays a crucial role in determining the thickness of the slab, as well as bending moments and shear forces. The type of support that holds the slab should be specified when designing the reinforcement requirements.

Slab Thickness

The span, loads, and deflection limits play a major role in determining the slab’s thickness, which should be determined based on the span-to-depth ratio. The thicker the slab, the less reinforcement it requires; however, it may be more expensive.

Reinforcement Layout

Two types of reinforcements are used when designing the roof slab: Main Reinforcement and Distribution Reinforcement.

- Main Reinforcement: It carries the load to the slab and is placed in shorter and longer spans.

- Distribution Reinforcement: These are the smaller reinforcement bars placed perpendicular to the main reinforcement to distribute the loads evenly across the slab.

Properties of Materials

The compressive strength of the concrete should withstand the imposed loads acting on the structure. The yield and tensile strength of the steel reinforcement should be within the design limits.

Step-by-Step Process of Roof Slab Reinforcement

Preparing the Site

The initial step in constructing the slab reinforcement is to prepare the site. This process includes ensuring the site is level, the foundation is strong enough to support the slab’s weight, and the supporting structures are properly cured.

Building the Formwork

After the site is prepared, the formwork is built to hold the concrete in place. The formwork is typically made of wood, steel, or aluminium. It should have precise dimensions and be strong and secure to keep the concrete in place before it sets.

Placing the Reinforcement

Place the reinforcement bars within the framework based on the design. The reinforcement should be laid based on the span, thickness, and grid pattern. Connect the grids to form a strong reinforcement framework.

Concrete Pouring

After placing the reinforcement rebars, the mixed concrete should be carefully poured into the formwork. Vibrators remove air voids and form a strong bond between the concrete and the bars. Complete filling the slabs and ensure no leakage or deterioration in the formwork.

Curing

After pouring the concrete, allow the RCC slab to set. After hardening, cure the roof slab periodically with water, keeping it moist and cool. The curing process takes several days until the concrete attains full strength and durability.

Demolding

Once the slab is completely cured and attains the strength to stand without the formwork, the moulds are removed, making it suitable for plastering, other construction, and electrical works.

Critical Considerations in Reinforcement Roof Slab

Dealing with Structural Discontinuities

Any structural discontinuity in the roof slab, such as openings, edges, and changes in slab thickness, has a major impact on the structure. However, it can be addressed carefully to maintain structural integrity.

Properly Calculate Reinforcement Slab by providing adequate edge beams, reinforcing the corners, and detailing the cut-off points with reinforcement bars to help distribute loads, prevent cracks, and resist stress

Handling Thermal and Shrinkage Stresses

Thermal and shrinkage stresses can be mitigated by providing necessary reinforcements to resist tensile stresses, placing control joints, and using high-quality concrete to reduce shrinkage levels.

Also, proper curing methods, controlled temperatures, joint sealing, and regular inspection could mitigate thermal stresses.

Crack Prevention Strategies

- Proper slab design with adequate reinforcement, control joints, and slab thickness should be properly calculated.

- High-quality concrete and steel bars can be used.

- Removing air voids during construction is mandatory.

- Regular and proper curing under controlled conditions is necessary.

- Use concrete cover to prevent the reinforcement from corroding.

- Regular maintenance and providing protective coating could enhance durability.

Conclusion

Roof Slab Reinforcement is an important structural component that enhances the tensile strength of concrete and prevents the structure from cracking and other deterioration. The reinforcement design should be carried out carefully to ensure the roof slab can withstand all loads on the structure. We hope this blog helps you understand roof slab reinforcement and its importance.