Steel decking transforms modern construction with its strength and faster installation. This kind of shaped steel sheet now appears in over 70% of commercial buildings worldwide. Studies show that steel decking can cut construction time by up to 40% compared to traditional methods.

Builders choose steel decking because it holds heavy loads while speeding up projects. The material serves as a base for concrete and adds strength to floors. Steel decking offers a smart solution that saves time and money as building costs rise. This blog explains the types, uses, and benefits of steel decking in today’s building industry.

What is Steel Decking?

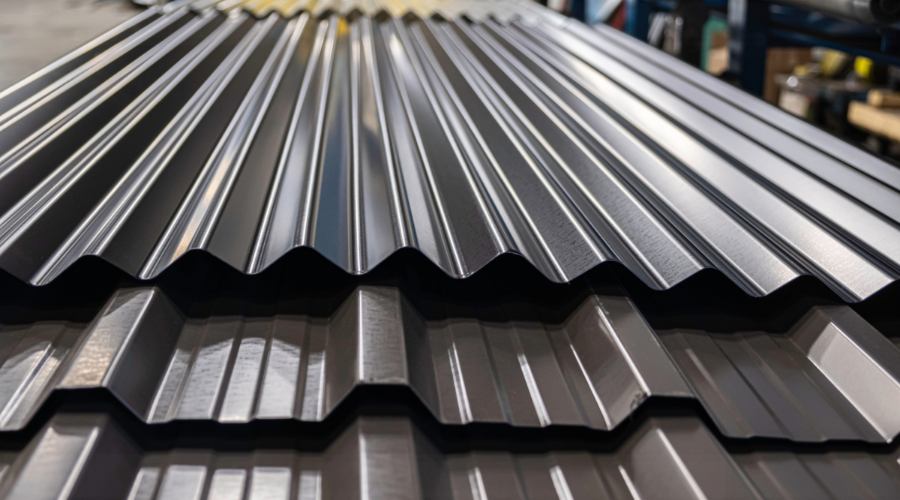

Steel decking, also known as metal decking, is a structural component made from cold-formed, corrugated steel sheets. These sheets are typically supported by steel beams or joists and serve as a platform for floors or roofs. Their ridges and valleys make them stronger, and their wavy shape helps the steel grip the concrete once it hardens.

Makers produce steel decking from coated steel that resists rust. The coating extends the deck’s life. Decking thickness can vary from 0.6mm to 1.5mm, depending on the holding weight.

Steel decking works with concrete to produce robust flooring. The deck first holds the wet concrete’s weight. After the concrete hardens, it sticks to the steel to form one strong unit. This teamwork between steel and concrete makes the floor stronger and stiffer.

Types of Steel Decking

1. Metal Roof Deck

Metal roof deck are used as the structural base for roofing membranes in commercial roofing construction. A steel roof deck is normally placed directly over structural steel members , serving as a working platform for the installation of insulation, weatherproofing, and other roofing products. An additional metal roof deck surrounds a building, protecting it from wind and providing adequate fire resistance in a UL roof assembly, along with snow, live weight, dead weight, and seismic and wind loads.

2. Floor Decking

Roof decking does not have that load-bearing capacity, so it is not used for pouring and curing concrete. Although both are made from similar lightweight materials and use similar construction and manufacturing practices, their uses are different. Concrete weight is handled by a specific type of floor decking. There are two types: composite decking, which forms a strong composite slab, and form decking, which is a permanent mold that does not contribute structurally

3. Composite Steel Deck

Composite steel floor deck, which features a ribbed pattern with embossments that are intended to connect with a concrete slab to form embedded ribs in a concrete slab, which functions as a permanent form and a positive reinforcement all at once. In commercial structures, an interlocking composite metal floor deck is most commonly used.

4. Non-composite Steel Deck

The non-composite form deck serves as a permanent steel pan for poured concrete slabs underneath the non-composite form deck. This offers a durable, protective, and safe stay-in-place form, along with a very autoregulatory, rapid, and low-cost installation. Such a type of deck does not create a composite action but supports the reinforced concrete very well. This, in turn, enhances the lateral stability of structural members while simplifying the slab-forming process. It is perfect for fast and stable concrete slab construction.

Applications of Steel Decking in Construction

Commercial Buildings

Steel decking is popular for commercial construction in offices, shopping centres, and hotels. It installs quickly, saving time and money. The system works well for the large open spaces needed in commercial buildings.

Industrial Facilities

Steel decking is used in factories and warehouses because it holds heavy loads. The system supports machinery and stored goods. Steel decking also allows for wide spaces that create flexible work areas.

Multi-Story Parking Structures

Parking garages use steel decking to create floors that support cars. The system handles the weight of moving vehicles, and steel decking lasts long even when exposed to car fluids and road salt.

Educational and Healthcare Facilities

Schools and hospitals use steel decking for fire safety and sound control. The system handles the complex service needs in these buildings, creating floors that meet strict safety standards.

Residential Buildings

Apartment buildings increasingly use steel decking. The system provides floor separation with good sound blocking and allows for fast construction of multi-family housing.

Steel Decking Installation Process

The following is the composite steel decking installation process.

Preparation

Before installation, workers check that support beams meet requirements, verify spacing, levels, and alignment, prepare safe paths for moving materials, and ensure that all needed tools are ready.

Deck Placement

Workers place steel deck sheets according to the plan drawings. They ensure sheets overlap properly. The team attaches decking to support beams using welding, screws, or special fasteners.

Edge Finishing

Installers handle building edges with special closures and stops. They put up safety rails to protect workers. The team prepares openings for stairs, elevators, and service shafts.

Connector Installation

Workers weld metal studs through the deck into support beams for composite systems. These connectors ensure that steel and concrete work together. The team tests the studs to ensure they’re attached properly.

Reinforcement and Concrete Pouring

Workers install wire mesh and steel bars as needed. Using pumps or buckets, they pour concrete to the right thickness. The team ensures that the concrete fills all spaces and finishes smoothly.

Steel Decking Design Considerations

Structural Performance

Engineers choose deck thickness based on span needs and weight requirements. They determine the concrete thickness for overall strength. The design accounts for both building and everyday use conditions.

Fire Safety

Designers specify the fire rating needs of the floor system. They select appropriate deck types and concrete thicknesses. The design may include extra fire protection like special coatings.

Sound Control

Projects with noise concerns require careful deck selection. Designers may choose cellular or deep profiles for better sound blocking, and the system often includes extra sound insulation materials.

Service Integration

The design plans for openings and holes through the deck. It accounts for electrical conduits and junction boxes. The team plans for heating ducts and plumbing needs.

Sustainability

Designers consider steel decking’s environmental benefits, specify recycled material requirements, and use materials efficiently to reduce environmental impact.

Benefits of Steel Decking

Faster Construction

Steel decking offers impressive building speed compared to old methods. Workers cover large areas quickly with minimal equipment. The system cuts labour costs and shortens project times.

High Strength with Less Weight

The material’s strength-to-weight ratio beats the alternatives. Steel decking creates lighter buildings that need less foundation support. This efficiency saves significant material costs.

Fire Resistance

Steel decking provides excellent fire protection when properly designed. The system achieves fire ratings up to four hours with the right concrete thickness. This performance ensures safety and meets building codes.

Durability and Low Maintenance

The material’s toughness delivers long-term performance benefits. Steel decking resists damage from water, pests, and fire. This long life reduces maintenance needs throughout the building’s life.

Design Flexibility

Steel decking’s flexibility works with many architectural designs. The system fits various building shapes and layouts. This adaptability gives architects freedom while maintaining structural strength.

Conclusion

Steel decking is an essential component of modern building technology. Its strength, speed, and versatility make it valuable across numerous construction projects. Builders appreciate how quickly it installs, while engineers value its performance. The material continues to improve with advances in manufacturing and design. As construction needs continue to increase, steel decking will be a great solution to build safe and efficient floor systems. Steel decking is still the best option for construction professionals seeking dependable, cost-effective structural solutions.