Precision and competence are essential factors to consider while erecting a steel framework to ensure effectiveness and safety. The erection process of steelwork includes assembling the steel components onsite. Before connecting the steel components, they must be positioned in the right place to ensure the stability of the steel components. Read on to learn all about steel erection, its types, processes and tools and equipment required.

Overview of Steel Structure Erections

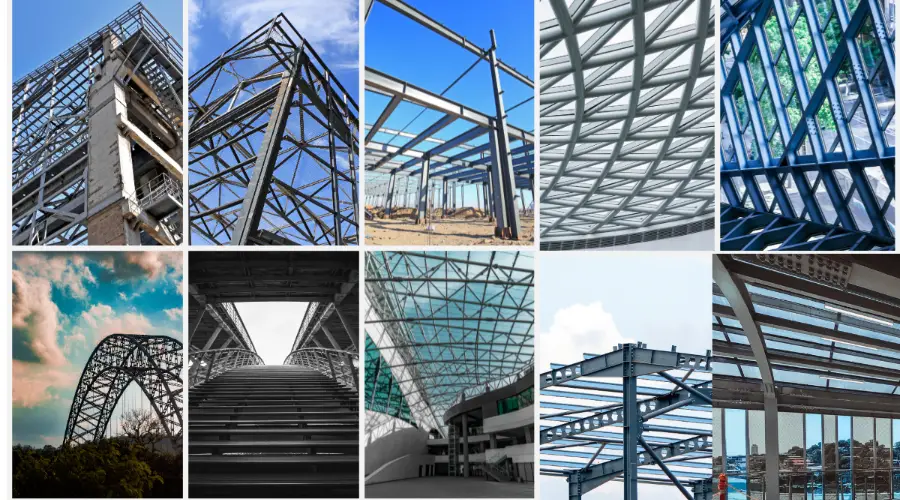

Steel can handle stress and deformation (ductility) and can be used for multiple applications like high-rise structures, bridges, and other structural components for its resilience and longevity. Steel structures are being built more commonly in today’s era to meet growing construction demands. The process of steel erection is complex and requires careful attention to detail to ensure safety of all the people involved.

Types of Steel Structures

- Steel Frame Structures

The most frequently seen structure is a steel frame, which is utilised in everything from residential projects to skyscrapers. Their resilient and firm framework is made up of horizontal beams, vertical columns, and connections made with bolts or welding.

- Steel Truss Structures

Uniform transfer of weight and enhanced stability can be achieved through interconnected triangles, which are used in steel truss systems. These frequently used roofs, bridges, and other steel structures have the strength to sustain over long periods of time.

- Steel Arch Structures

Buildings and bridges can be built using steel arch structures. The curved arch steel supports the whole weight of the structure and is produced by an arch formed with several interconnected steel components. These structures are built to withstand harsh weather conditions for enduring over long time periods.

- Steel Cable Structures

Steel cable structures create a suspension system by supporting a building’s weight with steel cables. Often utilised for roofs and suspension bridges, the cables are extended across the structure to offer support and are fastened to towers or columns at either end. Additionally, for increased stability, they are sometimes fastened to concrete blocks or the ground.

- Steel Space Frame Structures

To sustain the weight of a building, steel space frame structures employ a three-dimensional framework made of welded or bolted steel tubes. Large buildings such as sports arenas and airports frequently use these structures. Such structures are generally finished by covering the framework with cladding and roofing materials.

- Light Gauge Steel Structures

Light gauge steel buildings, which are frequently utilised for residential and small commercial buildings, have lightweight steel frames. These frames are constructed using thin sheet steel, cut into C or Z shapes, and fastened together using bolts or screws.

- Pre-Engineered Steel Structures

Pre-engineered structures are made by combining standardised and prefabricated parts at construction sites. These steel structures can be easily seen in industrial buildings such as warehouses, distribution centres, and factories.

Tools and Equipment for Steel Erections

At every stage of construction, certain materials, tools, and techniques are needed for erecting a steel building. Planning and knowing how to use the equipment is essential for ensuring quality and safety. The following is a list of the necessary resources and usage instructions:

- Mobile Devices

It includes equipment and vehicles used for material transportation and assembly, such as delivery trucks, cranes, and hoists. Only authorised equipment and certified operators are permitted on the property. Equipment must be kept at least 4.5 meters away from power lines that are 220V or higher. Unless there is an emergency, only one signalman is allowed to direct operators.

- Slings

To lift and carry heavy objects, slings like cables, chains, ropes, or webbing are utilised. Before using slings, check their durability. To avoid damage, cushion slings at sharp edges. To lessen the strain on slings, avoid jerking weights when lifting. Slings should be properly preserved while not in use.

- Support Structures

Workers can support the framework or perform operations at heights using movable platforms. Scaffolds must be set up on level ground with wooden platforms (at least 20 cm by 20 cm) serving as foot bases. Make sure scaffolds don’t obstruct cranes or other movable machinery. At least four times the planned load should be supported by scaffolds. For safety, outfit scaffolds with platforms, ladders, midrails, and handrails.

- The ELCB Box

Electrical shocks can be avoided by an Earth-Leakage Circuit Breaker (ELCB). Three-pin plugs, sealed boxes, and ELCBs with a 30–60 mA rating are required for electrical systems. For convenient access, at least one ELCB needs to be mounted on the roof.

- Manual Instruments

It requires basic hand tools such as drills, saws, clamps, and screwdrivers. To keep tools from falling, fasten them to your wrists. Give precise directions on how to utilise each tool. Steer clear of improvised or temporary tools.

Steel Structure Erection Steps

As erecting steel structures involves several risks and challenges, crucial steps must be followed for an effective installation process, as follows:

Step 1: Getting Ready for the Erection

Any project’s success depends on the calibre of its equipment and building supplies. Problems like inadequate or poor-quality materials and irregularities in the structural designs can cause delays in construction and lower the project’s quality. Before moving on, contractors must carefully examine and confirm that the equipment and materials match the necessary standards.

Step 2: Construction of Foundations

When constructing a steel structure, the foundation is the initial phase. Its kind is defined by the load of the building and the strength of the soil, which is established by a soil survey. Reinforced concrete pads or strip foundations are appropriate for mild or moderate loads since they transfer weight straight to the ground below.

Step 3: Installation of Columns

For most steel buildings, columns and beams serve as the main load-bearing support. Strict technical and production criteria must be followed throughout the installation to guarantee structural integrity, safety, and functionality. Columns are welded to base plates to connect them to the foundation; square or rectangular shapes are ideal for ease. To control production and transportation constraints, columns are connected every two to three stories. Splices are welded for circular columns and these are typically situated 0.6 meters above the floor.

Step 4: Erection of Steel Beams

Beams, which are normally 3 to 9 meters long (up to 18 meters in certain situations), carry weights (such as floors and roofs) to columns.

Connections from beams to columns:

- Easy Connections: For vertical loads, employ solutions like double angle or flexible end plates.

- Rigid Connections: Use full-depth or extended end plates for torsional and vertical loads.

- Beam-to-Beam Connections: End plates are used to join beams to each other. By installing brackets or notching, secondary beams are levelled with primary beams.

Step 5: Install the other components

The project’s basic structure is completed by the erection of the remaining components, such as small braces and additional rivets or bolts, once the main frame has been aligned and installed.

Step 6: Examine Before Complete Covering

The steel structure is carefully examined to make sure it is built correctly and prepared for the finishing procedures before moving on to the last phases. Any mistakes in this stage may affect the overall quality standard of the construction process.

Step 7: Installation of Floor Systems

Floors are put in either during or after the building of beams. They stabilise the structure and support vertical loads. Typical floor systems include:

- Composite floors with metal decking or concrete.

- Units made of precast concrete.

Conclusion

Steel buildings are affordable for medium to large-scale projects because of their sophisticated design and large-scale manufacturing. They arrive sooner than conventional materials, and inclement weather doesn’t postpone installation. Damage diagnosis and prevention are aided by their obvious deformation before failure. They are earthquake-resistant because of their lightweight design and robust joints. These structures provide easy expansion, flexible pipeline installation, and roomy interiors with up to 60-meter spans, making them a popular choice for many projects.

FAQ’s

Beams, columns, and trusses are used in steel erection to create the framework for buildings and bridges. The steel parts are lifted and positioned into position by cranes and hoists.

To guarantee precise, secure, and effective steel assembly, erection aids such as bolts, angle seats, or lugs are utilised. They are selected according to the particular requirements of every project.