When it comes to construction, joints are very important for structures’ strength and durability. They are essentially the areas where dissimilar materials of building adjoin and are necessary to allow motion control, enable expansion and contraction, and maintain integrity in a structure.

Different kinds of joints are used in different construction purposes such as connecting large concrete slabs or framing wooden structures. An understanding of joint types and their uses is what helps builders and engineers create stronger buildings that last longer. The various types of joints employed in constructing buildings are covered by this article.

Different Types of Joints used in Construction

1. Concrete Construction Joints

Concrete construction joints are used to join two concrete pours. These joints are needed when concrete pouring is done in stages. This is common in large projects.

- Large Concrete Slabs: When constructing a large building like a shopping mall, it is not possible to pour the entire floor at once. The construction is done in sections. Construction joints are placed where one section ends and another begins. For example, if you are building a mall floor, you pour one section today and another section next week. The construction joint ensures these sections bond well and act as a single piece, maintaining the floor’s strength and stability.

- Multistory Buildings: In many cases, each floor is individually cast when constructing tall buildings. For example, in the case of a high rise apartment block, the first storey is allowed to dry before pouring the second floor. It is these construction joints between floors which ensures that each floor line is properly connected leading to overall stability to the building. This is essential for the building to stand up against its own weight as well as external forces like wind and earthquakes.

2. Expansion Joints

Expansion joints allow for material to expand and contract. This happens due to temperature changes. They prevent cracks and structural damage by accommodating these movements.

- Bridges: Bridges expand and contract due to temperature changes. Expansion joints are placed at regular intervals to allow for this movement. For example, the Bandra-Worli Sea Link in Mumbai has expansion joints that allow the bridge to expand in the heat and contract in the cold. This prevents cracks and damage, ensuring the bridge remains safe and stable.

- Roadways: Long stretches of concrete roads can crack without expansion joints. These joints are placed at regular intervals to manage thermal expansion and contraction. For instance, highways have expansion joints to prevent the concrete from cracking due to the heat in summer and cold in winter.

3. Contraction Joints or Control Joints

Control joints, also called contraction joints, control where cracks occur in concrete. They do so by limiting shrinkage. These joints are intentionally placed to direct the cracks to a specific location.

Applications & Types:

Control Joints are categorized under two types:

- Sawed Joint: Created by sawing a groove into the hardened concrete.

- Formed Joint: Made by placing a strip into the fresh concrete, which is later removed to create a groove.

Concrete Floors: Contraction or control joints are mandatory in large industrial concrete floors because of their ability to prevent random cracking. A good example can be seen with factories that have spacious concrete floors. Such control joints as the concrete is drying will allow for any shrinkage of the flooring along those lines of weakness created when it was still wet, preventing cracking and allowing heavy machinery through.

Pavements: Contraction or control joints in concrete pavements aim at creating pre-determined crack locations. This kind of thing happens usually for sidewalks as well as driveways too . Think about a long drive leading up to a house; there are control points at equal intervals so that any cracks would form across these places keeping it smooth.

Walls: In general terms, there exists some fissure dividing large solid or brick walls into different parts. For example, in a long boundary wall, control joints are placed at intervals to prevent unsightly cracks and maintain the wall’s strength and appearance

4. Joints in Masonry/ Masonary Joints

Masonry joints are vital components in masonry construction, contributing significantly to the structural integrity, durability, and overall performance of masonry structures. These joints, filled with mortar, bind individual masonry units like bricks, stones, or blocks together.

Applications of Masonry Joints

Load Distribution:

Masonry joints are essential for distributing loads evenly across a structure, preventing localized stress that can lead to cracks or failures. In multi-story buildings, bed and head joints ensure that the weight of each floor is safely transferred down to the foundation, maintaining structural integrity. These joints also support superstructures like beams and slabs, ensuring they remain stable and anchored.

Thermal Movement Accommodation:

Masonry joints like control and expansion joints are vital for accommodating thermal movements due to temperature changes. In regions with significant temperature fluctuations, masonry expands and contracts, which can cause serious structural damage without appropriate joints. Control joints, placed at regular intervals, allow for slight movements, preventing cracks. Expansion joints, filled with flexible materials, provide space for the masonry to expand and contract without stressing the structure.

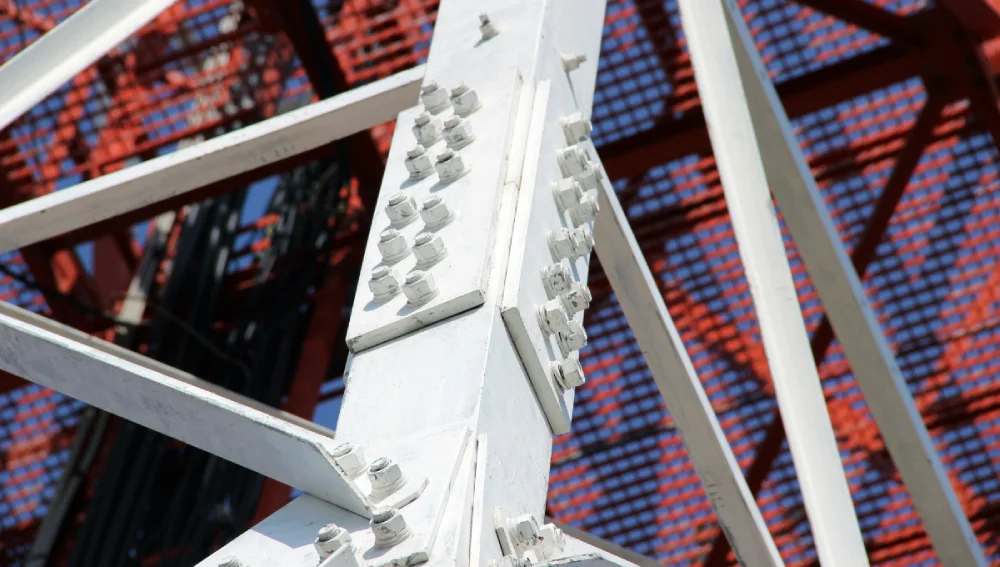

5. Dowel Joints in Concrete

Dowel joints use steel bars, called dowel bars, to connect two concrete elements. These joints add strength. They also ensure loads move between the connected parts. Dowel joints are essential in construction for connecting different concrete elements, providing strength, stability, and proper load transfer. These joints use steel bars, known as dowels, to ensure that the connected parts act as a single unit.

Applications:

Concrete Pavements: In large concrete pavements, straight dowel joints help transfer loads between slabs. For example, consider a long stretch of highway. The concrete is poured in sections, and straight dowels are inserted between these sections. When vehicles pass over, the load is transferred evenly across the slabs, preventing any single slab from sinking or lifting. This keeps the highway smooth and durable.

Industrial Floors: In warehouses or factories with heavy machinery and vehicles, straight dowel joints between concrete slabs provide stability. Assume a giant warehouse where forklifts and trucks continually move bulky stuff. The dowel joints prevent the floor from cracking or becoming uneven.

Sidewalks: For long sidewalks, straight dowel joints ensure the sections remain aligned and prevent shifting. In a busy city, these joints keep the sidewalks safe and even, reducing the risk of tripping or uneven surfaces.

6. Scarf Joints

We use scarf joints to join two pieces end-to-end. We do this by tapering or beveling them and then overlapping them. These joints are commonly used in woodworking and metalworking.

Application

Long Beams: In building traditional wooden houses, long beams are normally required as part of roof support systems. For instance, in an old Kerala house with sloping tiled roofs, long sticks of wood are laid across the shed to support it. When there is not enough timber, scarf joints are used to connect shorter pieces. Gluing and clamping the tapered ends of these pieces produces a strong and continuous beam that can hold up the roof.

Furniture Making: Scarf joints are also used in making furniture such as tables and chairs. For example, if a dining table has a long top made of wood which is too short then there might be a need for scarf jointing. These connections keep the table sturdy while maintaining its aesthetic character by ensuring that the joint is invisible when looked at closely because it becomes integrated into the design of the table itself.

Pipelines: In the construction of long pipelines, metal sections are often joined using scarf joints. For example, in an oil refinery, long pipelines are required to transport oil. Scarf joints ensure that the metal pipes are securely connected, providing strength and preventing leaks. The tapered ends of the metal pipes are welded together, creating a smooth and durable joint.

7. Isolation Joints

Isolation joints, also known as expansion joints or movement joints, are crucial components in construction. They are designed to separate different sections of a structure, allowing for independent movement between these sections. This separation helps mitigate the effects of various stresses such as thermal expansion, contraction, and settlement.

Technical Applications of Isolation Joints

Thermal Expansion and Contraction:

Isolation joints are crucial for managing the natural expansion and contraction of masonry materials caused by temperature changes. When temperatures rise, materials like bricks and concrete expand; when temperatures fall, they contract. Isolation joints, filled with flexible materials such as foam or rubber, compress and expand to absorb these movements. This flexibility prevents the formation of cracks that can compromise the structural integrity of a building.

Differential Settlement:

Differential settlement occurs when different parts of a building settle at different rates, which can lead to structural damage. Isolation joints are designed to handle this by allowing independent movement between adjacent sections of a structure. For instance, if a heavy multi-story building is constructed next to a lighter wing with different foundation conditions, isolation joints can prevent stress transfer and cracking. These joints ensure that each section can settle at its rate without affecting the other, thereby maintaining the overall stability and integrity of the building.

Conclusion

Understanding the different types of joints in construction is key. They ensure the stability, durability, and looks of a structure. Each joint type has its uses and traits. This makes it good for different tasks, maybe building a house, a bridge, or furniture. Knowing which joints to use will help you make a strong and lasting structure.

FAQS

Control joints are typically used in large concrete slabs, such as floors, pavements, and walls, to prevent uncontrolled cracking by directing the cracks along predetermined lines.

Expansion joints are crucial because they prevent damage by accommodating the expansion and contraction of materials, particularly in concrete structures, due to temperature changes. Without them, the building materials could crack or warp.

A construction joint is a point where two separate concrete pours meet, allowing for the continuation of construction work. An expansion joint, on the other hand, is specifically designed to absorb movement and prevent cracks due to temperature changes or structural shifts.