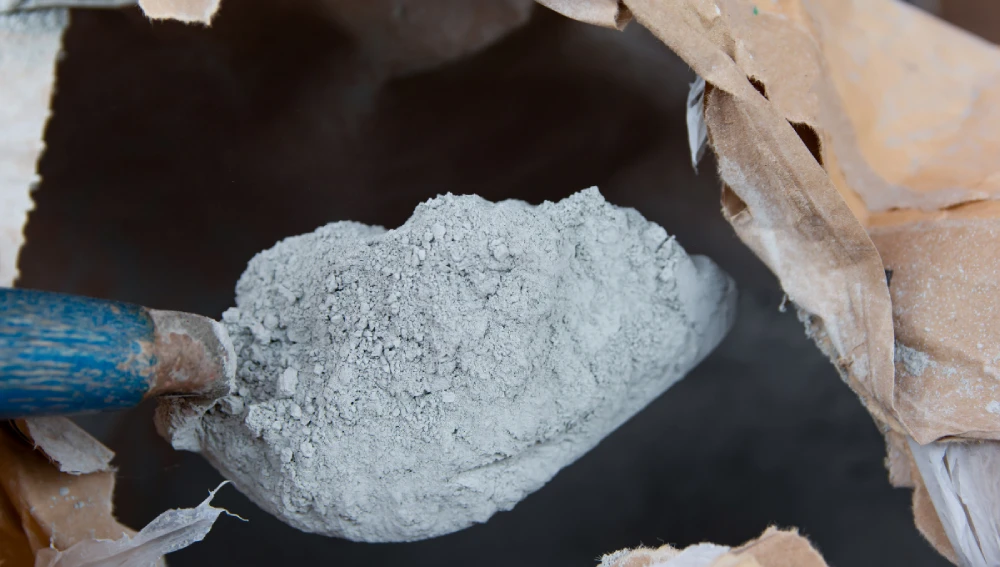

In most construction, ordinary Portland cement is an unsung hero. It is a versatile cement that can be blended with other materials to provide a propositioned cement ratio. Moreover, the cement is used for constructions starting from home to skyscrapers. This blog gives an insight about OPC.

What is OPC cement in Cement?

Ordinary Portland cement (OPC) is a cement type used commonly for construction. It is a binding material that can set, harden, and adhere to other materials. It helps in binding them together.

Chemical Composition Of OPC

The main components used in OPC are Calcium Oxide 60-67%, Silicon Dioxide 17-25%, Aluminum Oxide 3-8%, Ferric Oxide 0.5-6%, Magnesium Oxide 0.1-4% and Sulfur Trioxide 1-3%.

- After the chemical reaction, these materials exhibit various properties like, Tricalcium Silicate (C3S) provides early strength

- Dicalcium Silicate (C2S) gives later strength.

- Tricalcium Aluminate (C3A) helps in setting time and hydration heat.

- Tetracalcium Aluminoferrite (C4AF) helps in the maintenance of color. It also helps in overall strength.

Types of Ordinary Portland Cement

OPCs are categorized into different grades based on their compressive strength. This can be measured using megapascals. These grades indicate the strength and quality of the cement.

Here are some of the primary types of OPC,

OPC 33 Grade

The compressive strength is 33 MPa after curing for 28 days for OPC 33 Grade. It is generally used for common construction that does not need high strength. Their main applications are small residential buildings, flooring, and plastering.

OPC 43 Grade

The compressive strength is 43 MPa after curing for 28 days for OPC 43 Grade. They are used in reinforced concrete structures like columns, beams, slabs, and bridges. They provide a good balance between strength and workability.

OPC 53 Grade

OPC 53 Grade has a compressive strength of 53 MPa after 28 days of curing. There is high-strength cement. It is ideal for high-rise buildings, industries, and infrastructure projects like bridges and highways. They provide fast setting and hardening. This makes it suitable for construction work.

How is Ordinary Portland Cement Made?

The preparation of OPC involves various steps. First, the raw materials are converted into fine powders called cement. The overview of the process is as follows,

Grinding clay and limestone

Limestone and clay are extracted from quarries. Then they are crushed into smaller pieces. Then those materials are mixed in proper proportions and made into fine powder. This powder is called a raw meal.

Heat The Mixture

The raw meal that is obtained is added to the rotary kiln. It operates at temperatures of 1400 to 1500 degrees Celsius. At the end, clinker is produced.

Grind Clinker

After cooling the clinker, small amounts of gypsum is added. This helps in regulating cement’s hardening time. After that, the mixture is made into fine powders. These fine powders are OPC.

Key Ingredients of OPC

The following are the main chemical constituents of Ordinary Portland Cement:

| Lime (CaO) | 60 to 67% |

| Silica (SiO2) | 17 to 25% |

| Alumina (Al2O3) | 3 to 8% |

| Iron oxide (Fe2O3) | 0.5 to 6% |

| Magnesia (MgO) | 0.1 to 4% |

| Sulphur trioxide (SO3) | 1 to 3% |

| Soda and/or Potash (Na2O+K2O) | 0.5 to 1.3% |

The above constituents forming the raw materials undergo chemical reactions during burning and fusion, and combine to form the following compounds called Bogue Compounds

Uses & Qualities of Ordinary Portland Cement

Uses:

- Masonry and General Construction: Ordinary Portland Cement (OPC) is commonly used in masonry work, including bricklaying, plastering, and concrete production. Its versatile properties make it suitable for constructing buildings, pavements, and bridges.

- Construction in Standard Soil Conditions: The basic composition of OPC allows it to perform well in standard soil conditions, making it a preferred choice for a wide range of construction projects.

- Repair and Crack Filling: OPC is also used for filling cracks and performing structural repairs. Its relatively fast setting time is beneficial for quick fixes and emergency repairs, particularly in situations where time is a critical factor.

Qualities:

- Durability: Resists weather changes and chemical attacks.

- Workability: Easy to mix and apply in various construction jobs.

- Strength: Provides the strength needed for many types of structures.

Difference between Portland Cement & White Cement

Here’s how OPC differs from white cement:

| Differences | Portland Cement | White Cement |

| Color | Typically grey due to iron and manganese. | White because it has less iron and manganese. |

| Usage | Used for most general construction. | Used for special and decorative finishes. |

| Production | Made using standard methods. | Requires extra steps to remove impurities that affect color. |

Properties of Ordinary Portland Cement

Various properties have been shown by OPC as they can be used for multiple different construction purposes. Some of the properties are

Fineness

Fineness denotes the size of the particle in cement. If the cement is finer then the particle surface area will be greater. The surface area is needed for hydration purposes as this helps in the development of strength. They can be measured using the Blaine air permeability test.

Soundness

This helps in ensuring that cement does not undergo exceeding expansion. It may occur after setting, causing some cracks and structural failure. Soundness can be measured using the Le Chatelier test.

Compressive Strength

It is an important property for cement. This helps in determining the bearing capacity of concrete structures. Strength can be tested using cement mortar cubes. These measure the resistance to compression at various stages, such as 3 days, 7 days, and 28 days.

Setting Time

This refers to the time that it takes for cement paste to change its form. Normally it changes from a fluid to a rigid state. This has been classified into initial time setting and final time setting.

Initial Setting Time

The initial time setting is the time from which the water is added to cement to when it loses plasticity. The normal range is 30 minutes for OPC.

Final Setting Time

The final time setting is the time from which the cement paste turns into hardening. During hardening, they get sufficient strength. It normally occurs in 10 hours for OPC.

The following are some of the properties that define the performance of ordinary Portland cement in construction, ensuring its strength, durability, and reliability.

| Properties | Values |

| Specific Gravity | 3.12 |

| Normal Consistency | 29% |

| Initial Setting Time | 65mins |

| Final Setting Time | 275mins |

| Fineness | 330 kg/m2 |

| Soundness | 2.5mm |

| Bulk Density | 830 – 1650 kg/m3 |

Advantages of Ordinary Portland Cement

There are various advantages to using the OPC in construction. Some of the advantages of ordinary portland cement is explained below:

- Mainly, they have high strength that helps in faster completion of projects. Moreover, the strength can be customized by articulating the water-cement ratio. They are resistant to abrasion and are the perfect fit for high-traffic areas.

- Also, they are versatile. OPC can be used in slabs, beams, pavements, and foundations. Additionally they can be used with fibers, aggregates, or admixtures resulting in specific properties of concrete. This makes them useful for various construction purposes.

- Additionally, they are available widely and are also cost-efficient. This is because OPC are readily available in most parts of the world.

- Lastly, they offer durability and resistance to environmental factors.

Conclusion

OPC is a basic and important material used in construction. It is well known for its durability and also reliability. They have various grades that can be used for various constructions. OPC is a versatile cement that is used in pavements, and also in construction of skyscrapers. People often get confused between OPC and PPC but both are different and have a huge difference between them

FAQs

OPCs are categorized based on compressive strength into different grade types.

Dicalcium silicate helps in later strength development.

Soundness ensures that cement does not expand excessively after setting. This is for preventing cracks.

OPC generally has a shelf life of about three months if stored properly in a dry place. It is best to use it within this time to ensure it is effective.

Yes, OPC can be used for underwater projects, but it is better to use special cement designed for underwater conditions.

OPC starts gaining strength quickly, reaching about 70% of its strength in the first 7 days. It achieves full strength after 28 days.

OPC manufacture requires a large amount of energy, and CO2 emission occurs in the process. Measures are currently being taken to alleviate these effects and to look for less damaging solutions.